To lift, to move, to overturn

Italian production

Manual handling of a load can pose a risk when loads are too heavy or bulky, difficult to grasp, or unstable.

In assembly or production lines, hydraulic platforms are used as leveling work surfaces, allowing for the optimization of material loading and unloading operations.

For lifting and removing pallets, lifting platforms, housed in a pit or with a suitably shaped platform, facilitate loading/unloading operations.

Each solution is customized to best meet the individual needs of the various industrial application sectors.

A clear commitment to customers: product quality, professional service, flexibility of the production system

The invaluable technical and operational knowledge we've accumulated in various industrial sectors allows us to understand specific needs and requirements, always offering the most effective, functional, and cost-effective solution.

Characteristics

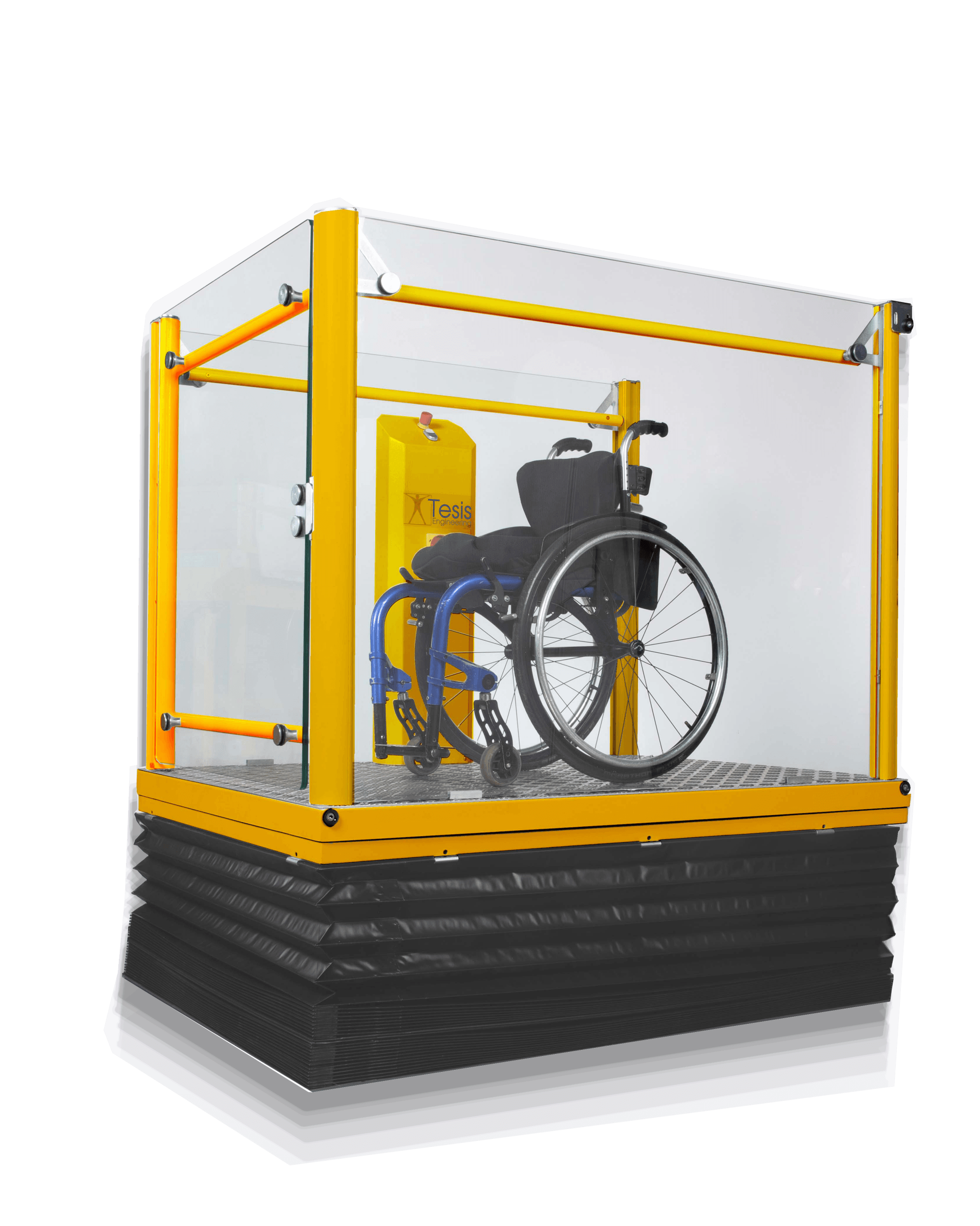

Hydraulic platform lifting tables, truly effective operational solutions

Basic Equipment

The basic lifting platforms are equipped with the following safety features as standard:

Sensitive frame along the lower perimeter of the platform, to stop the platform from descending in the event of contact with obstacles.

Parachute valve also functions as a speed limiter.

Low voltage controls, hold-to-run type.

Respect the safety distances required to prevent shearing and crushing risks.

Mechanical safety locks for maintenance operations.

Structure made of electrically welded folded sheet metal and profiles, forming a rigid and non-deformable assembly.

Lifting arms shaped and obtained with oxy-fuel cutting from very thick sheet metal.

All rotating parts slide on self-lubricating bearings or bushings chosen and sized according to the stresses.

Hydraulic jacks sliding on oleolite gaskets for high pressures

Some optional extras

Protective railings with or without gates.

Protective bellows under the floor.

90°/180°/360° rotating platform, manual or motorized.

Tilting or folding platform.

Base frame on wheels, with extractable drawbar for empty movement.

Connection flap in 1 or 3 sectors, for loading/unloading vehicles.

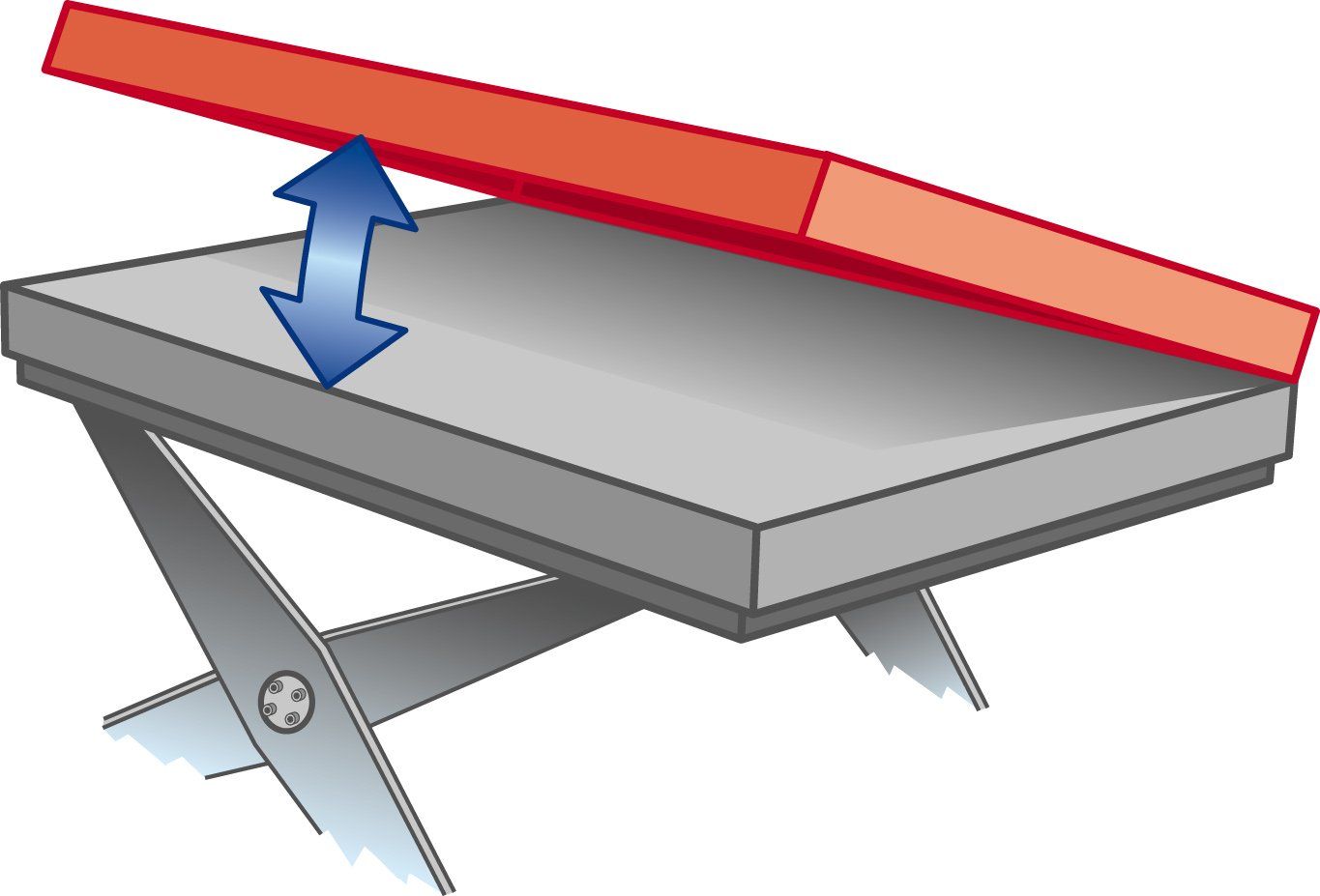

Sliding platform, manual or hydraulic.

Retractable or fixed flaps.

Special applications on request

Dimensions on request, capacities up to 50000daN - Standard or special versions (e.g.: versions for dusty environments, versions for refrigerated environments, stainless steel versions for food environments, versions with shaped or equipped platforms for the heavy steel industry)